Why a 3/4″ thick engineered hardwood floor beats the thinner options

Posted: April 14, 2025Author – Ryan Palma Owner/CEO Sustainable Lumber Co.

Click on these links to view our 3/4″ thick engineered White Oak and our 3/4″ thick engineered Hickory flooring, or email us for a pricing quote, or call us at 406-642-7120.

When it comes to engineered hardwood flooring, thickness matters more than you might think. While thinner options like 1/2″ or 3/8″ have their place, a 3/4″ thick engineered hardwood floor often takes the crown for durability, versatility, and that premium feel. If you’re weighing your flooring options, here’s why the 3/4″ version might just be the superior choice.

When it comes to engineered hardwood flooring, thickness matters more than you might think. While thinner options like 1/2″ or 3/8″ have their place, a 3/4″ thick engineered hardwood floor often takes the crown for durability, versatility, and that premium feel. If you’re weighing your flooring options, here’s why the 3/4″ version might just be the superior choice.

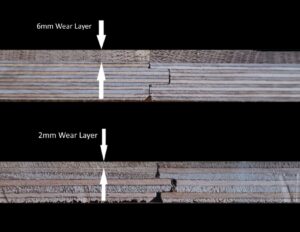

Engineered hardwood isn’t solid wood all the way through, it’s a real hardwood top layer (called the wear layer) bonded to a sturdy core of plywood or fiberboard. With a 3/4″ thick floor, that wear layer is usually beefier, typically 4mm or more, compared to the skimpy 1-2mm you might find on thinner floors. Why does this matter? A thicker wear layer can handle multiple rounds of sanding and refinishing caused by scratches, dings, dents, and wear over the years. No problem, just refinish it and keep it looking fresh. Some 3/4″ floors can last a lifetime with the right care, while thinner ones might tap out sooner.

Thicker floors aren’t just about the surface, they’ve got more material overall to resist the twists and turns of life. In most climates humidity spikes in the summer and drops in the winter. A 3/4″ engineered floor’s multi-layer construction helps prevent warping, cupping, or bowing better than thinner options. A thick engineered hardwood floor will also perform much better over radiant floor installations. With less thickness (like 1/2″ or 3/8″), there’s simply less structure to hold everything steady, making them more vulnerable to movement or damage over time.

Thicker floors aren’t just about the surface, they’ve got more material overall to resist the twists and turns of life. In most climates humidity spikes in the summer and drops in the winter. A 3/4″ engineered floor’s multi-layer construction helps prevent warping, cupping, or bowing better than thinner options. A thick engineered hardwood floor will also perform much better over radiant floor installations. With less thickness (like 1/2″ or 3/8″), there’s simply less structure to hold everything steady, making them more vulnerable to movement or damage over time.

Here’s where the 3/4″ thickness flexes its muscles: you can nail it down, glue it down, or even float it in some cases, just like solid hardwood. That gives you options to match your subfloor, your style, or your contractor’s skills. Thinner floors are stuck with floating or glue-only installs, which might not work for every space. Plus, the 3/4″ profile plays nice with uneven subfloors or transitions, making it a go-to for trickier projects.

Ever walked on a thin floor and felt like you’re tap-dancing on a drum? Thinner engineered floors can have that hollow vibe. A 3/4″ thick floor feels substantial underfoot and sounds quieter, more like the real hardwood deal. It’s a small detail that adds up to a big difference in how your home feels day-to-day.

Let’s talk resale. Buyers notice quality, and a 3/4″ engineered hardwood floor screams “built to last.” It’s closer to the look and longevity of solid hardwood, which can nudge up your home’s appeal (and price tag). Thinner floors might save you money upfront, but they can come off as a budget shortcut to savvy shoppers.

Let’s talk resale. Buyers notice quality, and a 3/4″ engineered hardwood floor screams “built to last.” It’s closer to the look and longevity of solid hardwood, which can nudge up your home’s appeal (and price tag). Thinner floors might save you money upfront, but they can come off as a budget shortcut to savvy shoppers.

PRO’s of a Thinner Engineered Floor – They’re cheaper, lighter, and good for tight spaces, like if you’re layering over an existing floor and can’t afford extra height. But if you’re in it for the long haul, craving that refinishing flexibility, or just want a floor that feels like an investment, 3/4″ is tough to beat.

A 3/4″ thick engineered hardwood floor isn’t just thicker, it’s stronger, more adaptable, and built to age gracefully. Whether it’s the thicker wear layer, the solid feel, or the installation freedom, it’s a choice that pays off in durability and style. So, next time you’re shopping for flooring, don’t just look at the finish, check the thickness. Your future self (and your home) will thank you.

Contact us:

Our knowledgeable team is here to answer any additional questions you may have. Call us today for a free quote on our sustainable wide plank hardwood flooring at 406-642-7120 or click here to submit an inquiry online. We look forward to helping you with your next project!